Bristol’s standing as a centre for innovation in composite technology for the aerospace, automotive, renewable energy and rail sectors has been boosted with a £28m expansion to its National Composites Centre (NCC).

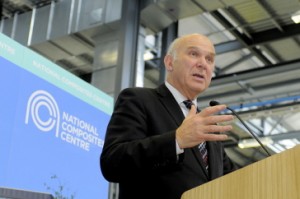

The expansion, which doubles the size world-leading research and technology hub, was officially opened yesterday by Business Secretary Vince Cable. It will create around 50 jobs at the NCC, with a further 30 to 50 within member organisations.

It will mean a much greater capacity to for the NCC, where highly-skilled engineers and technicians assist UK manufacturers to research, develop and commercialise new technologies and products.

The NCC is owned by the University of Bristol and based on the Bristol & Bath Science Park.

During his visit Dr Cable was shown an innovative racing yacht, lightweight road cars and the largest openly accessible high-rate manufacturing press for composites in Europe.

He was joined by more than 400 guests to see the new facilities at the NCC, funded by a £28m investment from Department of Business, Innovation and Science, via Innovate and the High Value Manufacturing Catapult.

As well as providing increased capacity and a dedicated high-speed composite manufacturing technology facility, there will be a new world-class training centre for higher level and vocational skills development. This will help train the next generation of engineers in composites manufacturing and technologies and bring together leading businesses, colleges and universities.

Professor Nishan Canagarajah, Pro Vice-Chancellor for Research at the University of Bristol, said: “The NCC is enabling multiple collaborations between industry and higher education partners, both nationally and internationally. Commercialisation of emerging technologies is a significant area of focus for our economy and the activities that take place here are an exemplar of that in action: world-class research combined with the entrepreneurial spirit of investigation and practical application.”

Peter Chivers, NCC Chief Executive, said: “The NCC is building the future for UK composites. We will work with companies to accelerate innovation and develop people to deliver commercially viable solutions.

“Thanks to the BIS capital investment, and HVM Catapult Core funding, we have now installed the world’s largest openly accessible high rate manufacturing press for composites manufacturing. This is aimed at supporting sectors such as automotive, where developing high-rate, low-cost manufacture of composite components is critical. This press is only in its first week of factory trials, yet it is already producing parts within just six minutes.”

The NCC has powerful support from industry. This year alone sees more than £14m of technology development work from industry pass through the centre.

After only three years, the NCC has nearly 40 members and has worked with more than 100 companies.